Celazole® U-Series

Celazole® U-Series products are used in some of the harshest environments — ranging from oil fields to aerospace to semiconductor applications. Parts made from Celazole® U-Series polymer perform well when exposed to conditions too severe for most plastics, and outperform other materials like polyimide, polyamideimide and polyetheretherketone in many extreme environments.

Celazole® PBI (polybenzimidazole) is a unique and highly stable linear hetrocyclic polymer. PBI is characterized by high strength; it exhibits excellent thermal stability, is hydrolytically stable after exposure to high pressure steam or water, is broadly resistant to hydrocarbons, alcohols, weak acids, weak bases, hydrogen sulfide, chlorinated solvents, oils, heat transfer fluids and many other organic chemicals.

HIGH TEMPERATURE PERFORMANCE

Celazole® PBI has a glass transition temperature of 800°F

HIGH STRENGTH

Highest compressive strength of any unfilled resin on the planet

CHEMICAL RESISTANCE

100% tensile strength after being submerged in motor oil at 200°F for 30 days

Celazole® U-Series

Celazole® U-Series (polybenzimidazole) compression molded products are suited for use in extreme and high temperature environments – ranging from oilfield to aerospace to semiconductor applications.

General Properties of Unfilled Celazole® PBI (U-60)

Highest Compressive Strength of Any Unfilled Thermoplastic

57 kpsi at yield

Excellent Tensile and Flexural Strengths

23 kpsi and 32 kpsi, respectively

Very Good Chemical, Steam, and Plasma Resistances

Outstanding Wear Resistance

Excellent Thermal and Electrical Insulator

Very Low Coefficient of Thermal Expansion

Excellent Hardness

High Volume Resistivity

Common Applications

Due to its high temperature, pressure, and chemical resistances, Celazole® U-Series (unfilled) is commonly used in extremely harsh environments. It is routinely molded and machined into precision parts for a wide variety of applications and industries including:

Semiconductor and flat panel display manufacturing, including LCDs and PVs (photovoltaics)

Electrical and heat insulating applications

Aerospace applications

Use as seals, bearings, and wear plates

Unfilled Celazole® U-Series (U-60)

The highest performing engineering plastic is ideally-suited for use in the most extreme engineering applications. At temperatures over 400°F (205°C), Celazole® U-Series exhibits the highest strength and stiffness of any unfilled plastic. It is even capable of withstanding brief exposure to temperatures as high as 1400°F (760°C) and performs best in an oxygen-free environment.

Reinforced Celazole® U-Series (U-60 ESD, U-60 CF, EZM)

Polymics, Ltd. is currently offering a 25% Carbon-Filled PBI (U-60 CF) and a 15% Carbon-Filled Static Dissipative PBI grade (U-60 ESD) in both standard and custom-sized compression molded shapes. In addition to the surface resistivity properties of the ESD grade, both products offer increased tensile and flexural strength (37 kpsi and 42 kpsi, respectively). Also, our unique EZM material is both more machinable and lower cost. Contact us for details!

Celazole® PBI U-60 Typical Properties Datasheet

Unfilled PBI

Celazole® U-60 is an unfilled PBI polymer and comes in a fine powder suitable for compression molding to achieve higher strength. U-60 is commonly molded and machined into precision parts for industrial, chemical and petrochemical industries; aerospace; glass making; and liquid crystal display (LCD) panel manufacture.

Celazole® PBI is ideal for applications where requirements cannot be met by other resins—in extreme high temperatures, in harsh chemical or plasma environments, or in applications where durability and wear resistance are important. Parts molded of Celazole® PBI are being used in semiconductor and flat panel display manufacture, electrical insulating parts, heat insulating applications, as well as seals, bearings and wear plates in various industrial applications. They are also being evaluated in demanding aerospace applications requiring outstanding strength and short-term high temperature resistance.

Parts are molded of U-60 grade Celazole® polybenzimidazole (PBI) resin, a unique organic polymer which does not burn in air and has extraordinary hightemperature resistance, along with excellent stability to chemicals and hydrolysis.

In high-temperature exposure to organic chemicals, Celazole® molded parts offer outstanding chemical resistance and property retention, even after extended exposures. In hot caustic, Celazole® parts out-perform other high-performance resins. And Celazole® U-60 parts have been used successfully in a variety of harsh environments, ranging from oil fields to aerospace applications. In the field, Celazole® parts have performed well when exposed to hydraulic and heat transfer fluids, chlorinated solvents, polyester, nylon, PEEK, and PES molten polymers, and metal-corrosion inhibitors – conditions too severe for most plastics.

Celazole® parts are hydrolytically stable after exposure to high pressure steam or boiling water. Moisture absorption of Celazole® U-60 resin reaches equilibrium at 10-14% and, through solvation, some strength loss and swelling occur. However, Celazole® parts typically regain their original properties after dehydration. When constrained, as in valve assemblies, Celazole® U-60 parts have been used successfully in high-temperature, high-pressure steam environments.

MECHANICAL

Tensile Strength

--- Modulus

--- Elongation

Tensile Fatigue, % of stress to failure at 1,000,000 cycles, 1 Hz

Flexural Strength

--- Modulus

Compressive Strength (Yield)

Compressive Strength (10% Strain)

Compressive Modulus

Hardness – Rockwell M

– Rockwell E

– Shore D

Izod Impact Strength (notched)

Izod Impact Strength (unnotched)

THERMAL

Heat Deflection Temp. (264 psi; 1.8 MPa)

Glass Transition

Coefficient of Linear Thermal Expansion

--- 75-300°F (25-150°C)

--- 390-570°F (200-300°C)

Limiting Oxygen Index

Thermal Conductivity 77°F (25°C)

ELECTRICAL

Dielectric Strength

Volume Resistivity

Dissipation Factor

--- 1 kHz

--- 10 kHz

--- 0.1 MHz

Dielectric Constant

--- 1 kHz

--- 10 kHz

--- 0.1 MHz

Arc Resistance

OTHER

Specific Gravity

Coef. of Friction, Static

--- Aluminum

--- Steel

--- Brass

Coef. of Friction, Dynamic

--- Aluminum

--- Steel

--- Brass

Water Absorption, 24 hrs at 73F

Datasheet Download (PDF)

MSDS Download (PDF)

Celazole® PBI U-60 CF Typical Properties Datasheet

25% Carbon Fiber reinforced PBI

Celazole® U-60 CF is an ultra-high strength carbon fiber reinforced compression molded PBI variant available as a stock shape. 25% CF reinforced PBI has 32 kpsi tensile strength, 42 kpsi flexural strength, and 65 kpsi compressive strength. Celazole® parts are hydrolytically stable after exposure to high pressure steam or boiling water. Moisture absorption of Celazole® U-60 resin reaches equilibrium at 10-14% and, through solvation, some strength loss and swelling occur. However, Celazole® parts typically regain their original properties after dehydration. When constrained, as in valve assemblies, Celazole® U-60 parts have been used successfully in high-temperature, high-pressure steam environments.

MECHANICAL

Tensile Strength

--- Modulus

--- Elongation (break)

Flexural Strength (yield)

--- Modulus

Compressive Strength

Compressive Modulus

Izod Impact Strength (notched 1/8")

Hardness Shore D

THERMAL

Glass Transition

Coefficient of Linear Thermal Expansion

--- 75-300°F (25-150°C)

--- 390-570°F (200-300°C)

ELECTRICAL

Surface Resistivity

OTHER

Specific Gravity

Carbon Fiber Content (nominal)

Datasheet Download (PDF)

MSDS Download (PDF)

Celazole® is a registered trademark is a registered trademark of PBI Performance Products, Inc.

We Provide Solutions

Regardless of the industry or end-use, we have the expertise to quickly and economically create the ideal polymer for the job.

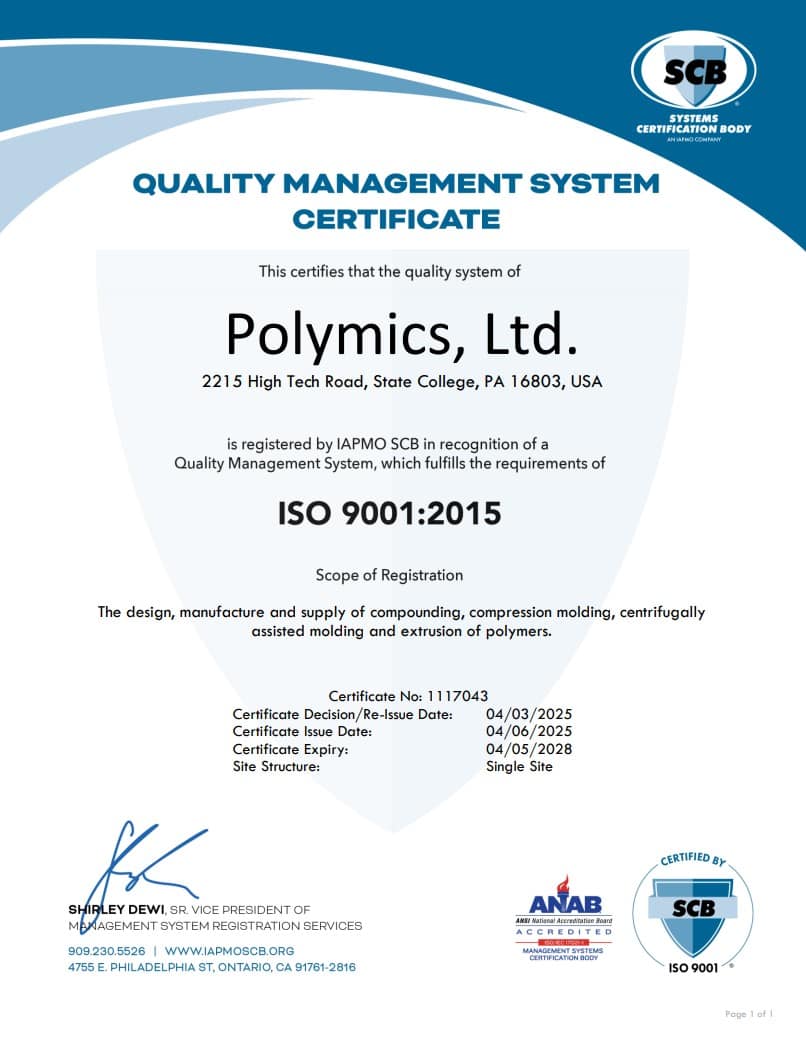

Polymics,® Ltd. is the only polymers company in the world that has the expertise and manufacturing capabilities to take customers from high performance thermoplastic material development to final part molding and assembly. Our in-house polymers engineering staff provides our customers with true one-stop “Problem to Finished Part Solutions” by working on their individual problem from start to finish.

Celazole® is a registered trademark of PBI Performance Products, Inc.

QUICK LINKS

Corporate Headquarters

2215 High Tech Road,

State College, PA 16803

Tel: 814.357.5860

Fax: 814.357.5863

Email: info@polymics.com

U.S. Sales Office

Asian Pacific

No.272, Huakang St.

Bade Dist., Taoyuan

Taiwan, 33464

Tel: 886.3.377.0518

Fax: 886.3.367.2115

Email: info@polymics.com

This information and all further technical advice are based Polymics’ present knowledge and experience. However, neither Polymics Ltd nor any of its affiliates makes any warranty, express or implied, including merchantability or fitness for use, or accepts any liability in connection with this information or its use. This information is for use by technically skilled persons at their own discretion and risk and does not relate to the use of this product in combination with any other substance or any other process. This is not a license under any patent or other proprietary right. The use of this product resides on the determination of the customer not Polymics Ltd. The customer must determine suitability of any information or material for any contemplated use, the manner of use and whether any patents are infringed. This information gives typical properties only and is not to be used for specification purposes. Polymics reserves the right to make additions, deletions, or modifications to the information at any time without prior notification.